I received an email from one of our customers who purchased an Eagle 7k four-post storage lift a few years back. He needed to move this lift closer to the front of his garage, about 3′. All Eagle 4-post storage lifts that range from 6k to 8k capacity have the ability to be moved because they are not anchored to the floor.

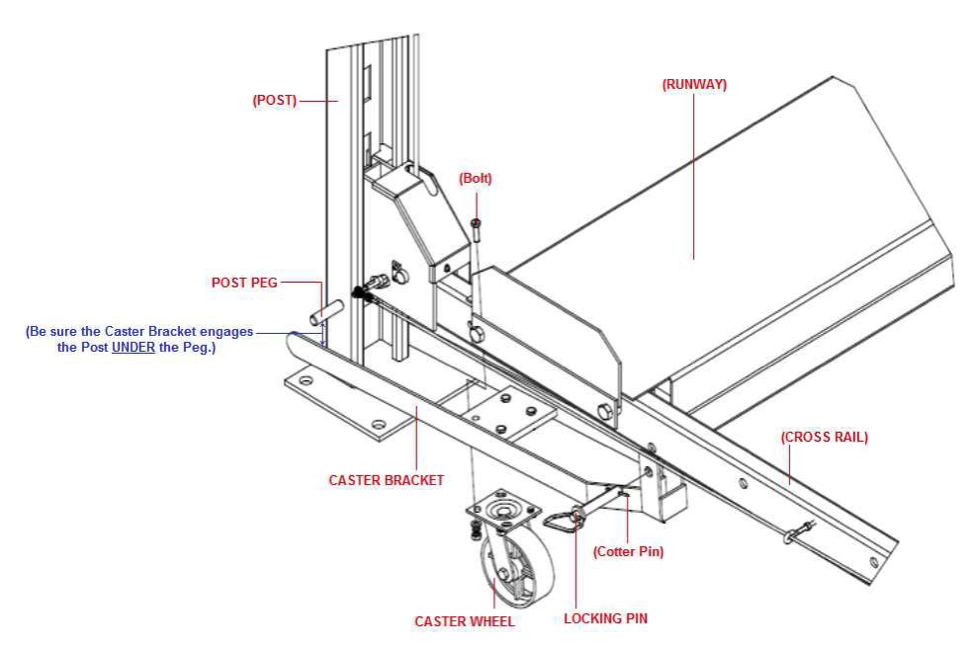

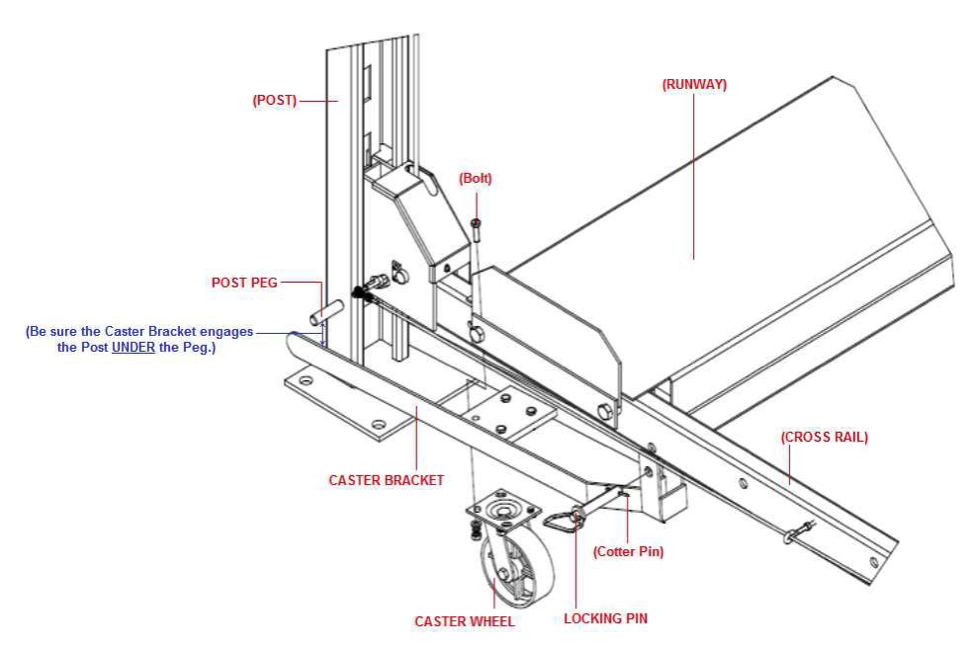

Our current storage lift models include a set of casters, but the older models do not. The casters hook to each post and allow the user to move the lift freely about his shop, as needed. The lift would lower and cause the forks on each caster to raise each post off the ground 1”-2”. See diagram below.

Customers who have the older models do have the option of purchasing casters from our parts department. If the lift is going to be moved frequently, then this is what we suggest. This buyer did not have the caster set, and really did not want to purchase a new set for $299 just to move the lift 3′, understandably. It was time for us to do some brainstorming together to solve this problem.

After thinking about how to make this work without the casters, I came up with 2 viable solutions for him to consider. Both solutions are only for short moves within your shop.

The first solution was to use a couple of floor jacks and some wood wedges. The user would need to lower the lift until it rested on top of the floor jacks. Once the lift is on the jacks, you would then need to put the wood wedges inside each post, on top of the cross member. These wedges would not allow the cross member to raise up when you begin to raise each jack. Once the lift is off the ground just enough for the lift to roll on the jacks, you begin to push the lift in the direction you wish the lift to go.

The 2nd solution requires a couple ratchet straps and 2 floor jacks. You would first lower the lift down onto the jacks, same as the first solution. Now with the ratchet straps, you would secure them from post to post sideways and on top of each cross member at the post. Once you tighten the straps, it will put the pressure needed on each cross member and not allow it to move once the jacks begin to rise. At this point you would raise the jacks until each post is off the ground enough to move the lift the short distance you need.

We recommend that if you are going to try and move your lift, that you do so carefully and safely.

I relayed both ideas to the customer and allowed him to make the decision which best suited him. This is what I heard back:

I wanted to thank you for your advice and counsel regarding moving my SS7000. I really appreciate Eagle’s customer focus.

Last night, a friend and I moved the lift forward 3’ and toward the garage door 6” with two floor jacks. The move took 5-7 minutes.

Figuring out how to lock the cross rail to the posts, so we could lift the entire assembly, took us about 20 minutes planning time. We wedged the post and side rail assembly with wooden wedges. Once the two were locked together, we lifted the entire assembly about 1”, as you suggested, and carefully pulled the lift forward and to the side slightly in gentle bursts. I have attached the “after” photo of our successful move.

Thanks, once again, for being supportive and helpful. Let me know what I can do to support Eagles’ business.

Sincerely,

Sean J. Rogers, Esq.

We’re so glad that we were able to assist in this “move”. This turned out great for the user and his desire to move his lift just a short distance. These applications are safe and easy to perform, but I would still recommend investing in the set of casters for any type of move. But remember, if you purchase our current 4-post storage lift models, the casters are included with every purchase … making these moves easy!

The man who became “The King” has been in racing for over 50 years. His daddy was a NASCAR driver. These treasures were more than cars… they told his story, and the stories of his son and grandson. That’s why they are kept, and stored with care.

The man who became “The King” has been in racing for over 50 years. His daddy was a NASCAR driver. These treasures were more than cars… they told his story, and the stories of his son and grandson. That’s why they are kept, and stored with care. The weight of the history that stood around me suddenly hit me, and goosebumps rose up. I almost forgot that I was there to get photos of the Eagle storage lifts. There were cars that Richard Petty drove, including his last win at Daytona. There was the car the Kyle Petty drove when he was at Wood Brothers Racing. There were even Adam Petty’s cars that were considerately covered. The legend that is the Petty family is not only in racing or in North Carolina, but in their life are abundant. They make you feel truly special and want you to take a part in their history.

The weight of the history that stood around me suddenly hit me, and goosebumps rose up. I almost forgot that I was there to get photos of the Eagle storage lifts. There were cars that Richard Petty drove, including his last win at Daytona. There was the car the Kyle Petty drove when he was at Wood Brothers Racing. There were even Adam Petty’s cars that were considerately covered. The legend that is the Petty family is not only in racing or in North Carolina, but in their life are abundant. They make you feel truly special and want you to take a part in their history.