Old man winter is on his way and there are some maintenance and preventative tasks that you should do to your vehicle to ensure it’s ready for the cold air … and safe to drive in what could be dicey conditions.

Old man winter is on his way and there are some maintenance and preventative tasks that you should do to your vehicle to ensure it’s ready for the cold air … and safe to drive in what could be dicey conditions.

TIP #1: FLUID LEVELS: Check all fluid levels to ensure that all are at the correct level for proper working order. Check your oil, transmission fluid, brake fluid, radiator coolant, and windshield wiper fluid. Consumer Reports suggests using an oil formulated for winter use: “Engine oil thickens when cold, making it harder for the engine to turn over. Check your owner’s manual for the manufacturer’s recommendation, but generally, you should be using a multi-viscosity oil that has a “W” in the viscosity index, signifying that it’s formulated for winter use. Typical formulas that are recommended for modern engines include 5W-20, 5W-30, and 10W-30, which provide good oil flow at low temperatures and can usually be used year-round.”

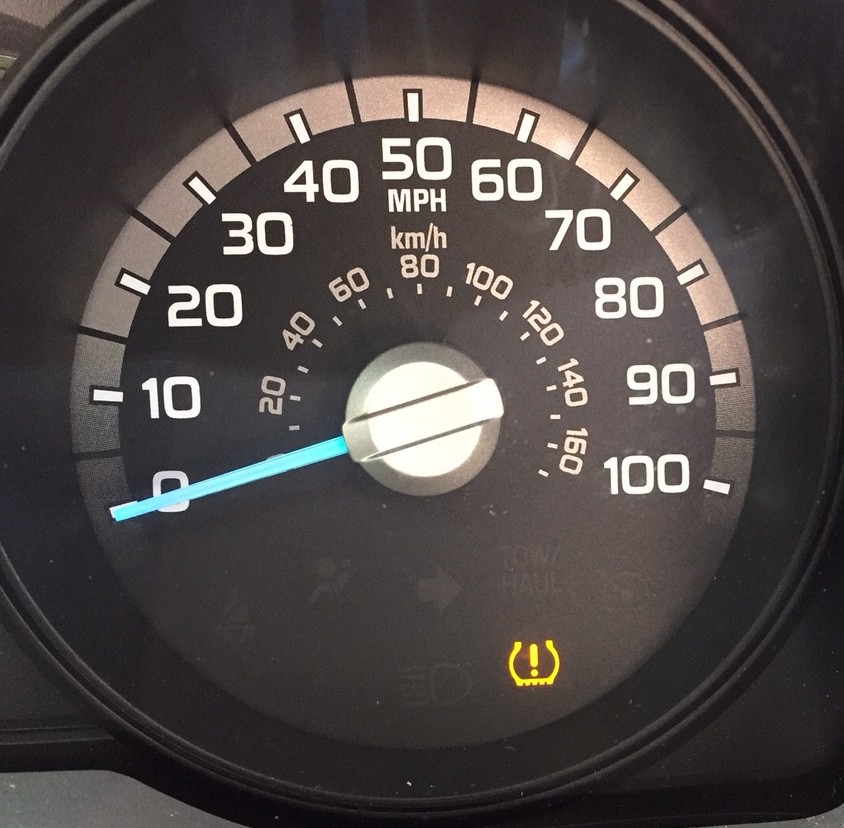

TIP #2: TIRES: Check your tire pressure and make sure they have plenty of tread. Bald tires on slick roads are a bad situation. Do you notice any abnormal wear on your tires, including your spare tire? Check & keep the proper listed amount of tire pressure for your tires at normal wear- you can deflate during snow and Ice situations.

TIP #3: BATTERY: Very cold temperatures can reduce a vehicle’s battery power by up to 50 percent. Have your battery serviced and load-tested to check its ability to hold a charge. If the battery is more than four and-a-half years old, it may be a good idea to replace it. Check your battery for corrosion and/or lose cables. If there is corrosion, you need to loosen and clean them with battery cleaner and a steel wire brush.

TIP #4: BRAKES: Winter conditions can cause debris to freeze on or around your brakes. This can cause you to be unable to safely stop in a winter slip.

TIP #5: KEEP IT FULL: Having a full tank of gas not only helps in the case of bad weather, but it also helps prevent moisture from freezing in the gas lines.

TIP #6: GET A TUNE UP

TIP #7: BE PREPARED: There are numerous sites that provide essential things to keep in your car. Here’s our short list for Winter Emergency Items to put in your trunk now:

- A flashlight, flares and a first-aid kit

- Seat belt cutter and window breaker. This one’s $7 on Amazon. Keep this in your glove compartment, not in your trunk, obviously.

- Make sure that all the proper tire-changing equipment is in the vehicle

- Jumper cables, a tool kit and tire chains

- Flares or reflective triangle, so you don’t get hit at the side of the road in the dark.

- Maps. Yes, the paper kind.

- A blanket (like the Mylar space blanket), warm clothes, hat and gloves

- Paper towels

- A bag of salt or kitty litter for added traction when a tire is stuck

- A snow brush, ice scraper and snow shovel

- Extra windshield washer fluid

- Extra food and bottled water

TIP #8: Change Your Lights – Proactively replace your fog, brake, and tail lights before they burn out. It’s relatively inexpensive and can help you avoid a dangerous situation if you find yourself in poor-visibility conditions.

TIP #9: Antifreeze– Antifreeze protects your engine from freezing in cold weather and it also cuts back on corrosion. It’s important to keep equal parts antifreeze and water in your radiator — a 50:50 ratio is considered the norm and will keep fluids from freezing at temperatures as low as -34 degrees Fahrenheit. Buy pre-mixed bottles of antifreeze and water.

TIP #10: Make Sure Your 4-Wheel Drive Works- Unless you go off-roading all year long, chances are if you own an SUV you don’t use your four-wheel drive (4WD) during the summer. Make sure that everything is working correctly before the winter starts. A functioning system can improve tire traction on snow and ice, decreasing the possibility of getting stuck. 4WD varies depending on the vehicle, so check the owner’s manual for the best environment in which to use it and how to engage the system.